Molecor: Excellence in Infrastructure Solutions for a Sustainable and Efficient Future

The choice of a particular pipe or material for the modernisation and upgrade of pressurised water networks is influenced by many components, sometimes technical ones, sometimes economic ones. The material choice for the pipes that will form the network should be based, among other parameters, on those that have to do with the durability of the installation such as: hydraulic capacity, the behaviour of the material facing the continuous transients that occur in a network, their robustness and lightness at the time of handling them, their ease of installation, the deterioration of the material with the passage of time, their roughness and as a consequence of this, their associated load loss, the availability in the market of the necessary fittings or the energy optimisation itself.

In addition, large-diameter pipes made of materials have been commonly used in supply networks, but there was no efficient solution that could combine the characteristics necessary to meet all of the factors mentioned before. Water supply networks made from those materials currently have a leakage rate of up to 25% of the water piped. In addition, chemical deterioration means that some pipes have to be replaced within a few years of being installed.

Molecor technology

In response to this,Molecor® is constantly researching the needs of the pressurised water pipe market and developing new efficient solutions, offering innovative products and responding to the challenges faced by today’s water supply market, making it a global leader in the development of technology for Oriented PVC (PVC-O) pipes. Molecular Orientation is a process that has been developed for fifty years, experiencing a great evolution that has been fundamental for the water transport sector. The technology developed by Molecor® is distinguished by its Genuine Air System, which uses air instead of water throughout the orientation process, increasing safety and optimising energy costs, thus contributing to sustainable development.

With this cutting-edge system, the company is able to manufacture the largest PVC-O pipes range in the world: TOM® pipes, as well as ecoFITTOM®, the first fittings made of this material, which guarantee greater uniformity in water transport networks by sharing the same physical and mechanical properties as TOM® pipes.

TOM® PVC-O pipes offer several advantages over other traditional materials, including: greater hydraulic capacity, allowing larger volumes of water to be transported for the same diameter; less pressure loss, resulting in lower energy costs; better performance in water hammer due to lower velocity; and excellent impact resistance. TOM® pipes provide the highest installation performance in metres/hour of assembly compared to other solutions, mainly due to their lightness, ductility, and ease of connection. The tightness they provide to the system prevents leaks and, therefore, water loss, which would result in a decrease in the volume of water supplied.

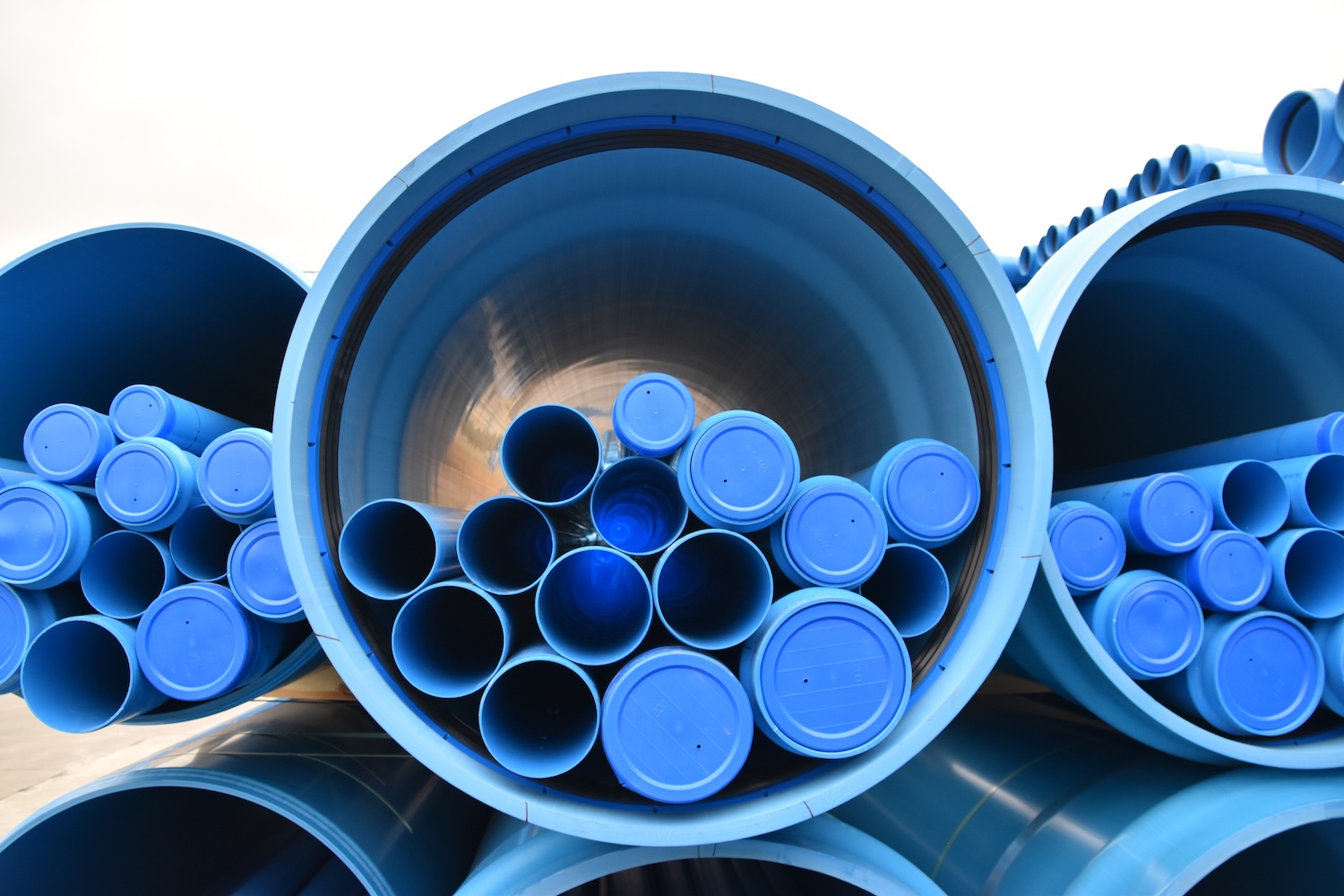

Large-diameters pipes

The need to expand the range of plastic solutions that fully meet these requirements for the durability of an installation is what has led Molecor® to develop a technological solution for the manufacture of TOM® PVC-O pipes with nominal diametres from DN90 mm to DN1200 mm, which were previously unavailable on the global PVC-O pipe market and which have represented a turning point in the sector, as their manufacture was unthinkable until the advent of Molecor®‘s technology. Furthermore, ecoFITTOM® offers a wide range available from DN110 mm to DN400 mm. This makes Molecor®’s TOM® pipes the most effective and comprehensive solution even for the most demanding projects, providing solutions for large-diameter projects that ensure longevity, resistance and reliability.

A recent example is the Maynilad project, carried out in the city of Caloocan, Philippines, where almost 3 km of DN1000 TOM® pipes are being installed.

Unlike other conventional materials, using TOM® has reduced installation time, lowered construction costs and minimised environmental impact. On average, 5-6 large-diameter pipes were connected per night, due to their lightweight nature and the fixed seal gasket, which simplifies pipe connection using only a lubricant. Pipe installation started on 14 October 2024, and as of 28 February 2025, 547 pieces have been installed over a span of 4.5 months. This trial project demonstrates a breakthrough in ease of installation compared to other pipelines of the same diameter.

All around the world, TOM® has stood out as the best solution for large-diameter projects, delivering the best results, not just once the project is done, but in the long run too.

In Seville (Spain), TOM® pipes were used for a project aimed at modernising the facilities of the La Vega de Coria T.M. irrigation community. The goal was to improve the water use efficiency by reducing losses in the system, optimise investment costs, ensure water availability for irrigation, improve water quality and reduce suspended solids in irrigation water, which was made possible by installing 18km of TOM® pipes.

In Serbia, TOM® pipes of different diameters are being used in a large-scale project spanning 22 km. Among them, more than 4km of DN1000 mm PVC-O TOM® pipes were installed in the Radljevo-Server coal mine project.

In Sevilla (Spain), a project was carried out with the aim of modernising the infrastructure of the irrigation community, which had an inefficient gravity-fed irrigation distribution system and limited consumption control. This resulted in improved water efficiency in these irrigation systems, with consequent water savings.

As seen, Molecor® keeps on consolidating its position as a leading company that delivers results that meet the demands of each project. Thanks to molecular orientation, the use of quality materials and the continuous pursuit of improvement, each project becomes a success that reaffirms the company’s drive and commitment to its customers.