BIO-UV Group Unveils New BIO-SEA Mini Ballast Water Treatment System for Low Flow Market

To meet increased demand for ballast water treatment systems from operators of workboats, yachts, research ships, OSVs, and similar-sized vessels, UV-based water treatment specialist BIO-UV Group has introduced what is arguably the smallest UV BWTS in the marketplace.

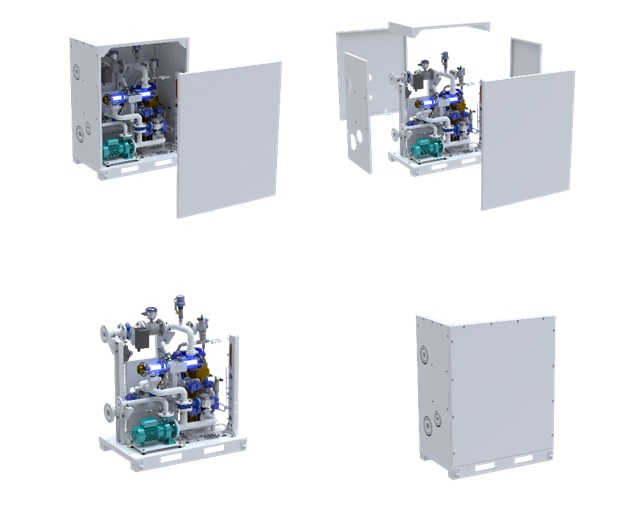

The new BIO-SEA L01-0030 Mini – more compact than the company’s existing low-flow BIO-SEA L range – is a fully automated filtration + UV-based system designed to treat ballast water flow rates between 13m3/h and 30m3/h from a unit that has a skid footprint of just 1m2.

Part of its “L” range (for flow rates from 13m3/h to 120 m3/h), the addition of the new L Mini means there is now a dedicated low-flow BIO-SEA BWTS for processing capacities below 30m3/h.

“We have been able to reduce system footprint and overall size without impacting performance,” said Pierre Decloedt, Technical Director, BIO-SEA by BIO-UV Group. “Essentially, what we have done is added component flexibility and reduced the height of the system – a key consideration when trying to fit a ballast water treatment system into a small machinery space. The L01-0030 Mini is the smallest, most compact BWTS we have designed for this market sector.”

Chemical-free, with zero active substances and by-products, the BIO-SEA Mini has been tested in low UV water transmittance conditions with performance unaffected by water temperature and salinity.

With a white gloss finish, CuNiFe pipework, high-quality components, filter choices, and drip tray as options, the L01-0030 Mini can be delivered as a covered skid allowing for installation in areas outside the machinery room, such as the hangar, garage, or indeed, an open space. A loose component modular version is also available.

“There are always space constraints, even on newbuild yachts. But we have listened to builders, managers, and owners to produce a compact, completely automated, plug-in-and-play BWTS that meets their dimensional and performance requirements,” he said.

BIO-SEA Unit Director Maxime Dedeurwaerder furthered that the development originates from a technical management company’s request to source a BWTS compatible with the machinery space dimensions of a yacht undergoing refit.

“The company couldn’t find a suitably sized BWTS and asked for a USCG extension until the Mini 30 was ready this summer.”

Dedeurwaerder confirmed that BIO-SEA by BIO-UV Group has already received orders for the new BIO-SEA L01-0030 Mini. “We have four firm orders since launching the Mini 30 in July, two of these orders are for newbuild superyachts and we are also in discussions with a Mediterranean yard to refit a 33m yacht with a BIO-SEA L01-0030 Mini modular version (loose components). If the project moves forward, it would be the smallest super yacht equipped with BIO-SEA BWTS.

“Any small ship that is mandated to comply with the BWM Convention now has a solution available that is certified to meet IMO & USCG standards. It is also future-proofed for more stringent rules should smaller vessels fall under IMO scrutiny, in coming years.”

Dedeurwaerder added, “In a fast-evolving marketplace, system flexibility, agility, and scalability are crucial in meeting current and future ballast water treatment requirements. By providing effective, high-performing turnkey BWT solutions with our customary short lead teams, we can remain the foremost provider of ballast water treatment systems for the low-flow market.”

BIO UV Group has a range of certified UV-based BWTS for all types of vessels and ballast water flow rates. The France-based listed company also provides 3D scanning, design, installation, commissioning, maintenance, and after-sales services as part of a complete turnkey BWTS package.

About BIO-UV Group

For more than 35 years, BIO-UV Group has been designing, manufacturing, and marketing water treatment systems using ultraviolet radiation (UV-C), ozone, AOP, and salt electrolysis for various applications including swimming pools, aquaculture, aquariums, industrial process water, wastewater and drinking water. In 2011, it added ships’ ballast water treatment to its range. The company’s products are manufactured in its specialized production sites in Lunel and Muret, France, as well as in Glasgow, Great Britain, allowing it to respond quickly to the specific requirements of its customers worldwide. The company, listed on the stock exchange since July 2018, has a consolidated turnover of 51.5 million euros in 2022 and a current workforce of 160 employees. More than 55% of the group’s sales are exported.

www.bio-uv.com