MIT Researchers Develop New Water Filtration Materials to Target PFAS

Water contamination from synthetic chemicals is rapidly emerging as one of the most pressing environmental crises worldwide. A recent report from the U.S. Centers for Disease Control revealed a startling statistic: 98% of individuals tested had detectable levels of per- and polyfluoroalkyl substances (PFAS), commonly referred to as ‘forever chemicals,’ circulating in their bloodstream. PFAS are notorious for their resistance to breaking down, persisting in the environment—and human bodies—for decades.

These chemicals are found in everyday products, from non-stick cookware and water-resistant clothing to firefighting foams and food packaging. The widespread use of PFAS has led to significant environmental contamination, with a recent study identifying over 57,000 contaminated sites across the United States alone. The U.S. Environmental Protection Agency estimates that addressing PFAS contamination could cost up to USD1.5 billion annually to meet stringent new drinking water regulations.

A Breakthrough in Water Filtration: Silk and Cellulose Membranes

Amidst this growing environmental challenge, researchers at the Massachusetts Institute of Technology (MIT) have developed an innovative filtration material that could revolutionise water purification. Made from natural silk and cellulose, this new material shows promise in removing a wide array of contaminants, including PFAS and heavy metals, while also boasting antimicrobial properties to prevent membrane fouling.

The findings, detailed in the journal ACS Nano, were authored by a team including MIT postdoc Yilin Zhang and professor of civil and environmental engineering Benedetto Marelli. Their research introduces a fully natural, protein- and cellulose-based solution that could provide a sustainable alternative to traditional water filtration methods.

Contamination by PFAS and similar compounds is actually a very big deal, and current solutions may only partially resolve this problem very efficiently or economically. That’s why we came up with this protein and cellulose-based, fully natural solution.

Yilin Zhang, MIT postdoc

Accidental Discovery Leads to Environmental Innovation

Interestingly, the technology behind this filtration material was not originally intended for water purification. Marelli’s team initially developed the silk-based nanofibrils to combat counterfeit seeds in agriculture, using a novel process that creates uniform nanoscale crystals from silk proteins through an environmentally friendly, water-based method.

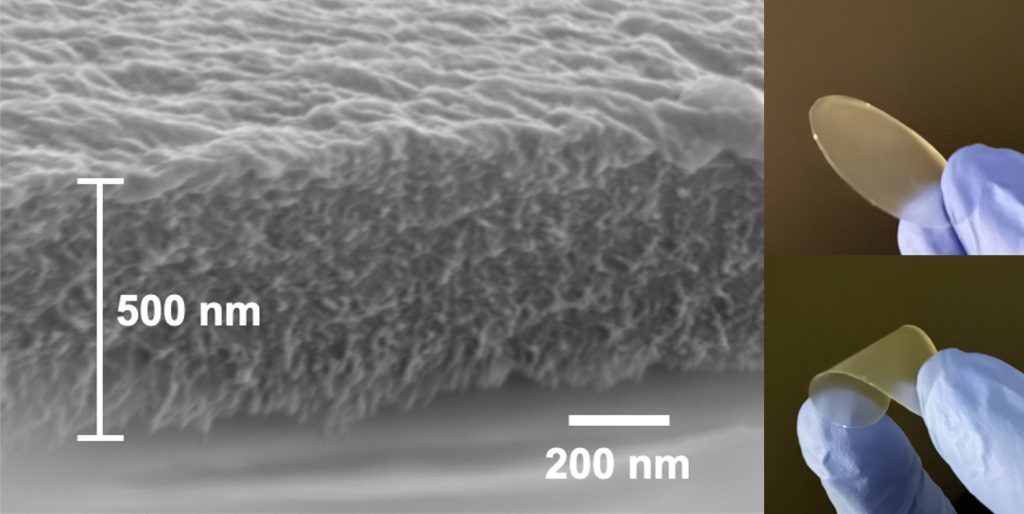

Recognising the potential of these nanofibrils, Zhang suggested they might be adapted for filtration. However, early tests with the silk material alone fell short. The team then incorporated cellulose—a readily available material often sourced from agricultural wood pulp waste—into the mix. The combination led to a breakthrough: silk molecules self-assembled along cellulose nanocrystals, forming a hybrid material with unique filtration properties.

The electrical charge of the cellulose added another unexpected benefit: antimicrobial properties that could significantly reduce the fouling of membranes by bacteria and fungi, a common problem in current filtration systems.

A Game-Changer in Water Filtration Performance

Lab tests have shown that the silk-cellulose membranes outperform standard filtration materials like activated carbon and granular activated carbon, particularly in extracting metal ions and emerging contaminants. The new material captured orders of magnitude more contaminants than these conventional options, making it a potential game-changer in water purification.

These materials can really compete with the current standard materials in water filtration when it comes to extracting metal ions and these emerging contaminants, and they can also outperform some of them currently.

Benedetto Marelli, Professor of Civil and Environmental Engineering

While the research provides a solid proof of concept, the team is actively working on improving the material’s durability and exploring alternative, more sustainable protein sources. The scalability of this solution remains a key focus, especially considering that the silk proteins used could face supply limitations if production is ramped up for global needs.

Potential Applications and Future Impact

Initially, the silk-cellulose filtration material could be utilised as a point-of-use solution, such as a filter attachment for household taps. However, Zhang envisions a future where this innovation could be scaled up to treat municipal water supplies, providing a robust defence against a broad spectrum of contaminants.

But before such large-scale applications can be realised, rigorous testing is needed to ensure that the filtration process does not inadvertently introduce any impurities. Fortunately, both silk and cellulose are considered food-grade materials, meaning the risk of contamination is minimal.

“Most of the normal materials available today are focusing on one class of contaminants or solving single problems,” Zhang noted. “I think we are among the first to address all of these simultaneously.”

A Path Towards Cleaner Water

The potential of this new filtration material extends beyond just PFAS and heavy metals. Its natural composition, coupled with the ability to address multiple contaminants simultaneously, positions it as a leading candidate in the next generation of water filtration technologies. If successful, it could provide a more sustainable, cost-effective approach to safeguarding the world’s water supplies.

The research team’s continued focus on enhancing the material’s properties and expanding the availability of its components will be critical as they look to transition from laboratory success to real-world application. In an era where clean water is increasingly at risk, such innovations provide a beacon of hope—and a reminder of the power of nature-inspired solutions.