Molecor SEA: Tailoring its Global Technologies to Local Conditions

Molecor Southeast Asia (Molecor SEA), the regional arm of Spanish innovator Molecor S.L., is a leading provider of sustainable and high-performance PVC-O piping systems for water infrastructure. Headquartered in Kuala Lumpur with a state-of-the-art manufacturing facility in Kuantan, Malaysia, the company serves the diverse needs of the Southeast Asian market by producing and marketing the TOM® and ecoFITTOM® ranges—known for their durability, efficiency and environmental benefits. Molecor SEA’s mission is to deliver innovative solutions that support resilient water supply and distribution networks, helping communities access clean and safe water.

Facing the region’s pressing challenges—ranging from aging infrastructure and high water losses to rapid urbanisation and climate change—Molecor SEA has tailored its global technologies to local conditions. Through advanced products, digital tools like geoTOM® and the TOM® Calculator, and strategic partnerships across Southeast Asia, the company plays a pivotal role in transforming water infrastructure in the region. With a strong alignment to the UN Sustainable Development Goals, particularly SDG 6, Molecor SEA is committed to driving regional progress in sustainable water management and sanitation access. Asian Water had the opportunity to talk to Walter Philip Pattynama, CEO of Molecor Southeast Asia recently on the company and its presence and development in the region.

Asian Water: Could you briefly introduce Molecor Southeast Asia and its core business focus in the water industry?

Pattynama: Molecor Southeast Asia, or Molecor SEA, is the regional subsidiary of Molecor S.L., a leading Spanish company headquartered in Madrid, Spain. Globally, Molecor is recognised for its innovation in high-performance piping solutions, with a strong presence in more than 30 countries. Our core business revolves around two key areas: we develop and manufacture the proprietary technology used to produce PVC-O (oriented polyvinyl chloride) pipes, and we also produce and market these advanced piping systems ourselves on a global scale.

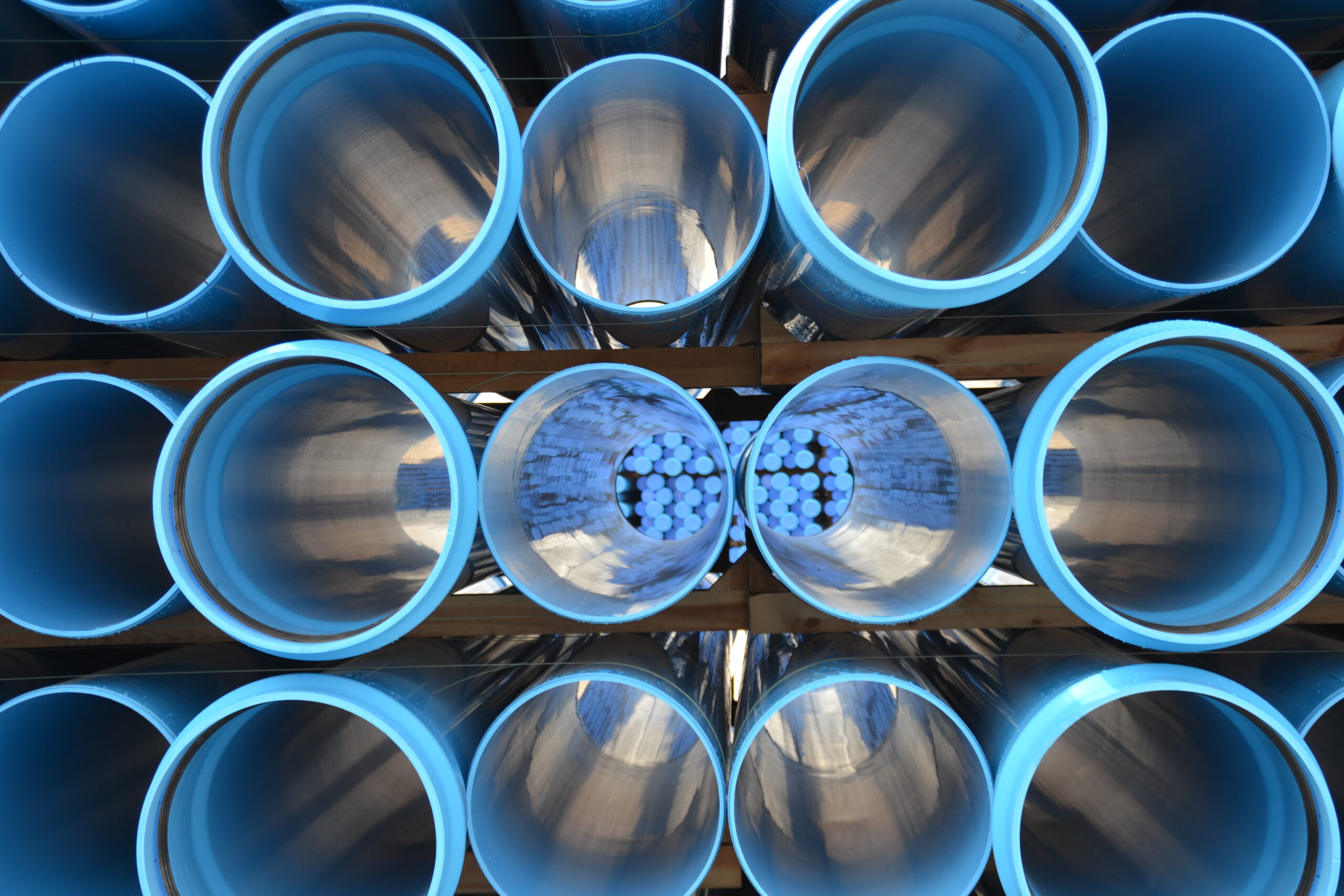

Molecor SEA, with HQ in Kuala Lumpur and a state-of-the-art factory in Kuantan, focuses on delivering sustainable and efficient water conveyance solutions tailored to the regional infrastructure needs of Southeast Asia. We manufacture the TOM® range of PVC-O pipes and the ecoFITTOM® line of PVC-O fittings, which are known for their superior mechanical strength, lightweight design, high hydraulic performance, and long-term durability.

These products are ideally suited for water supply, water transmission networks and water distribution networks. The use of PVC-O technology allows us to offer systems that are not only cost-effective but also environmentally responsible, contributing to more resilient and sustainable water infrastructure throughout Southeast Asia.

Our mission at Molecor SEA is to support the region’s water management challenges by providing innovative, reliable, and eco-efficient solutions that help ensure access to clean and safe water for all.

Asian Water: What are the most pressing challenges currently facing the water industry in the Asia Pacific region and how has the company adapted its global solutions to the specific needs and challenges in the Southeast Asian PVC-O pipe manufacturing market?

Pattynama: The water industry in Asia Pacific faces several critical challenges—aging infrastructure, high levels of non-revenue water (NRW), rapid urbanisation, climate change impacts and limited funding for upgrades. These issues strain existing systems and highlight the need for more resilient, efficient and cost-effective solutions.

At Molecor SEA, we’ve adapted our global PVC-O pipe technology specifically for Southeast Asian conditions. Our TOM® pipes and ecoFITTOM® fittings are designed to tackle these challenges head-on. They are lightweight, corrosion-resistant and offer a longer lifespan; helping reduce water loss, lower maintenance costs and simplify installation. With high hydraulic capacity and diameters up to DN1200mm, they are ideal for water supply, transmission, and distribution networks.

By combining advanced technology with local market insight, we aim to support the region’s need for sustainable, future-ready water infrastructure

Asian Water: How would you assess the region’s progress toward sustainable water infrastructure and leakage reduction?

Pattynama: Southeast Asia has made meaningful progress in strengthening water infrastructure and reducing leakage across many urban centers. However, significant challenges remain. Especially in rural and underserved areas. Despite development efforts, around 30% of the population in Southeast Asia still lacks access to safe drinking water, which underscores the urgency of expanding and modernising water systems across the region.

At Molecor SEA, we are committed to supporting this transformation through our high-performance PVC-O solutions. Our TOM® pipes and ecoFITTOM® fittings are engineered to deliver long-term efficiency and durability, significantly reducing water losses, maintenance costs and environmental impact. These attributes are essential in helping water utilities meet growing demand while tackling high levels of non-revenue water (NRW).

We’re seeing strong growth in market adoption, as more water authorities recognize the clear benefits of PVC-O; especially its ability to lower costs and drastically reduce leakage, which in turn improves service reliability and resource conservation.

Our involvement in regional events in all countries in the region such as ASIAWATER, Philippines Water, Thai Water and the Singapore International Water Week (SIWW) reinforces our commitment to being part of the solution. At the core of our efforts is Molecor’s mission: to improve the quality of life for people everywhere in the world, bringing affordable water within their reach through innovative, efficient and sustainable solutions. We believe that by aligning our technology with local needs, we can help Southeast Asia move closer to universal access to safe, clean water.

Asian Water: What are some of Molecor Southeast Asia’s latest product or technology innovations introduced in the region?

Pattynama: While access to safely managed drinking water remains a critical challenge in Southeast Asia, an even larger proportion of the population (over 45% according to recent estimates) still lacks access to safely managed sanitation services. This gap highlights the urgent need for reliable and sustainable sewage and drainage infrastructure across the region.

In response, Molecor SEA has expanded its product portfolio to include specialised solutions for sewage and drainage systems. We have already successfully introduced these PVC-O pipes in some projects in countries like Malaysia and the Philippines, and we expect more deployments in other markets, including Vietnam and Cambodia, where demand for effective and durable sewage infrastructure is urgent.

Beyond sanitation and drainage, Molecor recently launched an innovative product in Europe that we are preparing to bring to Southeast Asia also: the TR6® PVC-O pipes, designed specifically for irrigation applications. These pipes are considered among the most sustainable on the market due to their significantly lower carbon footprint and reduced energy consumption during their entire service life.

We plan to manufacture TR6® pipes at our Kuantan facility and introduce them soon to meet the growing agricultural irrigation needs in Southeast Asia, providing efficient water management solutions that align with the region’s sustainability goals.

Asian Water: Can you share recent projects or partnerships that demonstrate Molecor’s growth and impact?

Pattynama: Molecor SEA has been actively involved in various projects across Southeast Asia. For instance, the company has installed TOM® pipes in multiple locations in the Philippines, including DN1000 in Jaro City, Iloilo with Metro Pacific Iloilo Water District (MPIW) and Caloocan City with Maynilad Water District (MWD) for water transmission pipelines. In Malaysia, we are actively installing for non-revenue water (NRW) projects such as in Johor and Kelantan and also, for micro hydro projects with a local electric provider in Kuala Lipis, Pahang.

Additionally, Molecor SEA has organised technical seminars and participated in local & international events like the Singapore International Water Week and Vietnam Water Week showcasing its commitment to addressing water challenges through collaboration and innovation.

Asian Water: How is Molecor integrating digital technologies or smart water solutions into its offerings?

Pattynama: Embracing digital transformation, Molecor has developed geoTOM®, a mobile application designed to facilitate the geolocation and digital layout of canalization projects. This tool allows users to create intuitive digital maps of pipeline networks, providing detailed information on each component’s exact position, regardless of material or manufacturer. Such digital solutions enhance project planning, execution and maintenance, contributing to smarter water management.

Complementing this is the TOM® Calculator, an online tool designed to assist engineers, project planners, and installers in selecting the appropriate PVC-O pipe for their specific needs. The calculator enables users to input key project parameters—such as flow rates, pressure requirements and pipe diameters—and receive optimal product recommendations based on hydraulic performance and efficiency. This ensures technically sound decisions that reduce water loss, improve energy efficiency and align with long-term sustainability goals.

Together, geoTOM® and the TOM® Calculator exemplify Molecor SEA’s commitment to smart water solutions, enabling its partners to build more resilient, data-driven infrastructure across Southeast Asia.

Asian Water: On the sustainability front, how is Molecor contributing to the UN Sustainable Development Goals, particularly SDG 6 (Clean Water and Sanitation)?

Pattynama: Molecor SEA aligns its operations with the United Nations Sustainable Development Goal 6, which aims to ensure availability and sustainable management of water and sanitation for all. The company’s products support this goal by improving water-use efficiency and reducing leakages. Moreover, Molecor’s manufacturing process utilises a Genuine Air System, replacing traditional boiling water methods with high pressurised air, resulting in lower energy consumption and reduced CO₂ emissions. This environmentally friendly approach also contributes to other SDGs, such as SDG 7 (Affordable and Clean Energy) and SDG 13 (Climate Action).

Asian Water: Finally, what are Molecor’s strategic priorities in Southeast Asia heading into 2025?

Pattynama: Looking ahead, Molecor SEA aims to expand its presence in Southeast Asia by focusing on sustainable infrastructure development and technological innovation. The company plans to continue participating in key industry events, to engage with stakeholders and promote its advanced PVC-O solutions. By addressing regional water challenges through tailored products and digital tools, Molecor SEA strives to contribute significantly to the region’s water security and infrastructure resilience.