Desalination may be key to averting global water shortage, but it will take time

Clean freshwater is critical for sustaining human life. However, 1.1 billion people lack access to it worldwide. Desalination represents an increasingly popular way of addressing this.

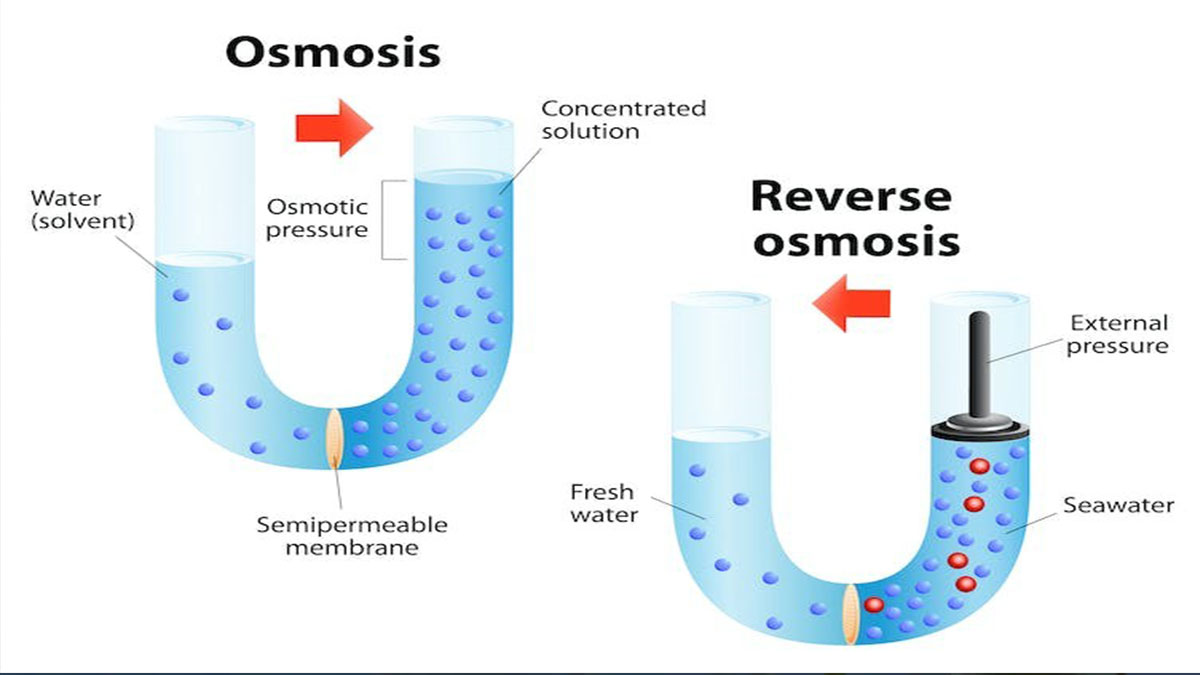

Desalination is the process of extracting salt from saline water to make it drinkable. There are two main types of desalination.

In the first – called thermal desalination – heat is used. This produces water vapour that condenses on pipes into fresh water. This process remains dominant across the Middle East, where nearly half of the world’s desalinated water is produced.

The second process is membrane desalination, commonly referred to as reverse osmosis. This process is used in 60% of plants worldwide. Saline water is forced under high pressure through a semi-permeable membrane whose pores are too small for the salt molecules to pass through.

Where is desalination used?

Desalination is used to extend drinkable water supplies beyond what is naturally available. Water-scarce regions are therefore particularly reliant on the technology. Desalination provides the United Arab Emirates with 42% of its water needs.

Because of the minimal cost of pumping, desalination is most economical in large coastal locations. However, our changing climate is contributing to increasing water shortages in typically mild regions, necessitating the expansion of desalination plants further inland and from brackish water. China, the US, and South America are all expanding their desalination capacity.

While desalination may be a technology capable of countering global water shortages, there are issues regarding its cost and efficiency.

Why does desalination remain so expensive?

Large amounts of energy are required to drive the process. This is particularly true for thermal desalination, where energy costs represent up to half of a plant’s entire production cost.

The reverse osmosis process generally has a lower energy requirement. However, treating highly saline water remains energy intensive. This is because higher salinity means more pressure is needed to force the water through the membrane.

Heavily polluted water sources must also be treated before desalination, requiring costly infrastructure such as sedimentation tanks and filtration systems. Treatment prevents the accumulation of debris on membrane surfaces that may impede the reverse osmosis process.

Treatment costs will grow as reliance on desalination increases and the process is applied to polluted and inland brackish water sources. Facing an increasingly dry climate, California now has 23 desalination plants that turn brackish water into drinking water.

Producing one litre of drinking water also creates 1.6 litres of brine, a highly saline waste product that can damage the environment. Brine deposits on the sea floor can lead to the destruction of sea ecosystems, while brine discharge reduces the oxygen content of seawater.

The safe disposal of brine is expensive. Most of the brine that is produced is pumped back into the sea, subject to environmental quality standards. If brine discharge does not meet these standards, then it requires further treatment.

Brine can be treated in evaporation ponds or diluted with a separate water source before being discharged. The prohibitive cost of brine treatment remains a significant barrier to the wider application of desalination.

Can desalination become cheaper?

Reducing the energy intensity of the process may deliver considerable cost reductions. Technologies such as forward osmosis, which allow desalination to occur at lower temperatures and pressures, are in development.

While promising, these technologies remain in their infancy. The market is small and there are few commercial installations. Technological evolution takes time, and further development will be required to ensure these processes can produce drinkable water on a commercial scale.

Developing more durable membranes will also reduce the cost of desalination. Using different materials, Japanese manufacturers have constructed membranes that successfully reject salt particles at low operating pressures. This both reduces the cost of replacing membranes and the energy requirement of the process.

Desalination could also be powered by cheaper sources of renewable energy. Solar-thermal technologies can generate direct heat, which can then be used to evaporate seawater. The Metito solar desalination plant under construction in Saudi Arabia will initially have the capacity to produce 30,000 cubic metres of drinking water per day.

However, solar desalination technology is littered with complexities. Solar energy supply is inconsistent and energy storage technology remains expensive, impeding its wider application. Therefore, most solar desalination projects are too small to produce drinking water for commercial use.

Novel solutions for brine management must also be further explored.

Brine can be recycled within the desalination process. The use of waste brine in the manufacture of sodium hypochlorite, a chemical disinfectant that can substitute chlorine, is a promising development.

Research has shown that on-site sodium hypochlorite production can save Caribbean desalination plants more than £300,000 per year.

Desalination facilities can further exploit waste brine through processes such as electrolysis, where brine is decomposed into simpler substances through electric currents. Future studies should investigate the potential of using the by-products of this electrolysis, hydrogen and salts, for energy production.

Despite growing water insecurity worldwide, desalination technology remains too expensive for widespread use. Efforts have been made to reduce its cost, with many showing promise. However, technological evolution takes time and it will be decades before costs fall to a level that facilitates the wider expansion of desalination – Credit: Kiran Tota-Maharaj, Reader in Civil and Environmental Engineering, Aston University